Highly acclaimed Manufacturer & Supplier of Blind Flanges, BLRF Flanges, Carbon Steel Blind Flanges, Stainless Steel Blind Flanges, Alloy Steel Blind Flanges, Nickel Blind Flanges, Inconel Blind Flanges, Hastelloy Blind Flanges in India & Asia

We are largest manufacturers of Blind Flanges & have huge stock of 304 Blind Flanges, 316 Blind Flanges, astm a105 Blind Flanges, astm a182 Blind Flanges as per asme / ansi B16.5 blind flanges, ansi B16.47 blind flanges, Din blind flanges, jis blind flanges & uni blind flanges Standards.

we offer high quality Blind Flanges in all size, classes & dimensions like Class 150 Blind Flanges, Class 300 Blind Flanges, Class 900 Blind Flanges, Class 1500 Blind Flanges, Class 2500 Blind Flanges, pn16 blind flange dimensions & pn40 blind flange dimensions

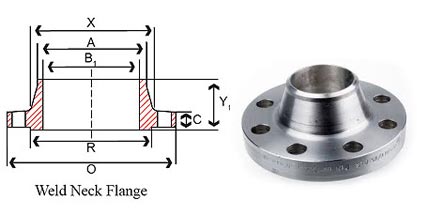

Weld Neck Flanges / WNRF Flanges

- Weld Neck Flanges Flanges Price

- Leading manufacturer of Weld Neck Flanges

- Our Live Stock of Weld Neck Flanges

- Weld Neck Flanges Application

Petromet Flange Inc. is a largest Manufacturer, Supplier and Exporter of Welding neck Flange, WN forged Flange, welding-neck Flanges, ASME 16.5 Weld Neck Flanges / WNRF Flanges in forged steel, Stainless Steel, AS,CS etc. Weld Neck Flange is flanges that designed to be joined to a piping system by butt welding. This kind of flange include lots of specification,Weld neck Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting, but is preferred for high stress applications. The necks, or hubs, transmits stresses to the pipeline. The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck flange. The bore of Weld-Neck flange matches bore of the pipeline, reducing turbulence and erosion. Weld Neck Flanges are available in following specifications:

Specification

- Type: WN Forged Flange , Weld Neck Flanges – WNRF

- Material:

Stainless Steel Weld Neck Flanges :ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

Carbon Steel Weld Neck Flanges: ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70

Alloy Steel Weld Neck Flanges: ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Duplex Steel Weld Neck Flanges: ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Nickel Alloy Weld Neck Flanges: Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22, C276, Copper Nickel, Hastelloy, Nickel, Monel, Inconel, Alloy20. - Standard: ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 ,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10 - Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- Size: 1/2-78 inch (DN15-DN2000)

- Pressure: ANSI class 150,300,600,1500,2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

- Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

- E-catalogue: Available , please visit catalogue of flange

- Usage: Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc.

ASME/ANSI B16.5 150LB WN Flange/Standards, Dimensions & Weight

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Hub Diam. Chamfer of W.N | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | A | Y | B | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 21.30 | 47.80 | 15.80 | 60.50 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 26.70 | 52.30 | 20.80 | 69.90 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 33.50 | 55.60 | 26.70 | 79.30 | 15.80 | 4 | 1/2″ | 1.1 | 2.4 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 42.20 | 57.20 | 35.10 | 88.90 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 48.30 | 62.00 | 40.90 | 98.60 | 15.80 | 4 | 1/2″ | 1.8 | 4 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 60.50 | 63.50 | 52.60 | 120.70 | 19.10 | 4 | 5/8″ | 2.7 | 6 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 73.20 | 69.90 | 62.70 | 139.70 | 19.10 | 4 | 5/8″ | 4.4 | 9.8 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 88.90 | 69.90 | 78.00 | 152.40 | 19.10 | 4 | 5/8″ | 5.2 | 11.5 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 101.60 | 71.40 | 90.20 | 177.80 | 19.10 | 8 | 5/8″ | 6.4 | 14.2 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 114.30 | 76.20 | 102.40 | 190.50 | 19.10 | 8 | 5/8″ | 7.5 | 16.6 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 141.20 | 88.90 | 128.30 | 215.90 | 22.40 | 8 | 3/4″ | 9.2 | 20.2 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 168.40 | 88.90 | 154.20 | 241.30 | 22.40 | 8 | 3/4″ | 11 | 24.3 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 219.20 | 101.60 | 202.70 | 298.50 | 22.40 | 8 | 3/4″ | 18.4 | 40.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 273.10 | 101.60 | 254.50 | 362.00 | 25.40 | 12 | 7/8″ | 25.5 | 56.2 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 323.90 | 114.30 | 304.80 | 431.80 | 25.40 | 12 | 7/8″ | 37 | 81.4 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 355.60 | 127.00 | 476.30 | 28.50 | 12 | 1″ | 51 | 113 | |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 406.40 | 127.00 | 539.80 | 28.50 | 16 | 1″ | 61.5 | 136 | |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 457.20 | 139.70 | 577.90 | 31.80 | 16 | 1 1/8″ | 71.5 | 158 | |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 508.00 | 144.50 | 635.00 | 31.80 | 20 | 1 1/8″ | 85 | 187 | |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 609.60 | 152.40 | 749.30 | 35.10 | 20 | 1 1/4″ | 119 | 262 | |

Note:

1) 2 mm raised face regularly furnished on Classes 150 and 300 unless otherwise ordered.

ASME/ANSI B16.5 300LB WN Flange/Standards, Dimensions & Weight

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Hub Diam. Chamfer of W.N | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | A | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 21.3 | 52.3 | 15.7 | 66.5 | 15.7 | 4 | 1/2″ | 0.8 | 1.8 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 26.7 | 57.2 | 20.8 | 82.6 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 33.5 | 62 | 26.7 | 88.9 | 19.1 | 4 | 5/8″ | 1.7 | 3.7 |

| 1-1/4″ | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 42.2 | 65 | 35.1 | 98.6 | 19.1 | 4 | 5/8″ | 2.2 | 4.8 |

| 1-1/2″ | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 48.3 | 68.3 | 40.9 | 114.3 | 22.4 | 4 | 5/8″ | 3.2 | 7 |

| 2″ | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 60.5 | 69.9 | 52.6 | 127 | 19.1 | 8 | 5/8″ | 3.6 | 7.9 |

| 2-1/2″ | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 73.2 | 76.2 | 62.7 | 149.4 | 22.4 | 8 | 3/4″ | 5.4 | 12 |

| 3″ | 80 | 209. 5 | 28.4 | 117.3 | 127 | 88.9 | 79.2 | 78 | 168.1 | 22.4 | 8 | 3/4″ | 7.3 | 16.1 |

| 3-1/2″ | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 101.6 | 81 | 90.2 | 184.2 | 22.4 | 8 | 3/4″ | 8.9 | 19.6 |

| 4″ | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 114.3 | 85.9 | 102.4 | 200.2 | 22.4 | 8 | 3/4″ | 11.8 | 26 |

| 5″ | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 141.2 | 98.6 | 128.3 | 235 | 22.4 | 8 | 3/4″ | 16 | 35.2 |

| 6″ | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 168.4 | 98.6 | 154.2 | 269.7 | 22.4 | 12 | 3/4″ | 20.2 | 44.6 |

| 8″ | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 219.2 | 111. 3 | 202.7 | 330.2 | 25.4 | 12 | 7/8″ | 31.2 | 68.8 |

| 10″ | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 273.1 | 117. 3 | 254.5 | 387.4 | 28.4 | 16 | 1″ | 44.3 | 97.5 |

| 12″ | 300 | 520. 5 | 50.8 | 374.7 | 381 | 323.9 | 130. 0 | 304.8 | 450.9 | 31.8 | 16 | 1 1/8″ | 63.5 | 140 |

| 14″ | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 355.6 | 142. 7 | 514..4 | 31.8 | 20 | 1 1/8″ | 86 | 190 | |

| 16″ | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 406.4 | 146. 1 | 571.5 | 35.1 | 20 | 1 1/4″ | 112 | 247 | |

| 18″ | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 457.2 | 158. 8 | 628.7 | 35.1 | 24 | 1 1/4″ | 141 | 310 | |

| 20″ | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 508 | 162. 1 | 685.8 | 35.1 | 24 | 1 1/4″ | 173 | 382 | |

| 24″ | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 609.6 | 168. 1 | 812.8 | 41.1 | 24 | 1 1/2″ | 248 | 546 | |

Note:

1) 2 mm raised face regularly furnished on Classes 150 and 300 unless otherwise ordered.

ASME/ANSI B16.5 1500LB WN Flange/Standards, Dimensions & Weight

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Hub Diam. Chamfer of W.N | Length Hub | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | A | Y | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 21.3 | 60.5 | 82.6 | 22.4 | 4 | 3/4″ | 2.1 | 4.6 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 26.7 | 69.9 | 88.9 | 22.4 | 4 | 3/4″ | 2.7 | 5.9 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 33.5 | 73.2 | 101.6 | 25.4 | 4 | 7/8″ | 3.9 | 8.6 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 42.2 | 73.2 | 111.3 | 25.4 | 4 | 7/8″ | 4.5 | 9.9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 48.3 | 82.6 | 124 | 28.4 | 4 | 1″ | 6.2 | 13.7 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 60.5 | 101.6 | 165.1 | 25.4 | 8 | 7/8″ | 11.3 | 24.9 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 73.2 | 104.6 | 190.5 | 28.4 | 8 | 1″ | 16.3 | 36 |

| 3″ | 80 | 266.7 | 47.8 | 133.4 | 88.9 | 117.3 | 190.5 | 25.4 | 8 | 7/8″ | 21 | 46.3 |

| 4″ | 100 | 311.2 | 53.8 | 162.1 | 114.3 | 124 | 235 | 31.8 | 8 | 1 1/8″ | 31.8 | 70.1 |

| 5″ | 125 | 374.7 | 73.2 | 196.9 | 141.2 | 155.4 | 279.4 | 35.1 | 8 | 1 1/4″ | 59 | 129.8 |

| 6″ | 150 | 393.7 | 82.6 | 228.6 | 168.4 | 171.5 | 317.5 | 31.8 | 12 | 1 1/8″ | 72 | 158 |

| 8″ | 200 | 482.6 | 91.9 | 292.1 | 219.2 | 212.9 | 393.7 | 38.1 | 12 | 1 3/8″ | 124 | 273 |

| 10″ | 250 | 584.2 | 108 | 368.3 | 273.1 | 254 | 469.9 | 38.1 | 16 | 1 3/8″ | 207 | 456 |

| 12″ | 300 | 673.1 | 124 | 450.9 | 323.9 | 282.4 | 533.4 | 38.1 | 20 | 1 3/8″ | 306 | 674 |

| 14″ | 350 | 749.3 | 133.4 | 495.3 | 355.6 | 298.5 | 558.8 | 41.1 | 20 | 1 1/2″ | 416 | 917 |

| 16″ | 400 | 825.5 | 146.1 | 552.5 | 406.4 | 311.2 | 616 | 44.5 | 20 | 1 5/8″ | 567 | 1250 |

| 18″ | 450 | 914.4 | 162.1 | 596.9 | 457.2 | 327.2 | 685.8 | 50.8 | 20 | 1 7/8″ | 736 | 1623 |

| 20″ | 500 | 984.3 | 177.8 | 641.4 | 508 | 355.6 | 749.3 | 53.8 | 20 | 2″ | 929 | 2048 |

| 24″ | 600 | 1168.4 | 203.2 | 762 | 609.6 | 406.4 | 901.7 | 66.5 | 20 | 2 1/2″ | 1504 | 3316 |

Note:

1) 7 mm raised face regularly furnished above Class 400 unless otherwise ordered.

ASME/ANSI B16.5 2500LB WN Flange/Standards, Dimensions & Weight

| Nominal Pipe Size | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Hub Diam. Chamfer of W.N | Length Hub.Y | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | A | Y | BC | BH | BN | BD | ||

| 1/2″ | 15 | 133.4 | 30.2 | 42.9 | 21.3 | 73.2 | 88.9 | 22.4 | 4 | 3/4″ | 3.2 | 7 |

| 3/4″ | 20 | 139.7 | 31.8 | 50.8 | 26.7 | 79.2 | 95.3 | 22.4 | 4 | 3/4″ | 3.6 | 8 |

| 1″ | 25 | 158.8 | 35.1 | 57.2 | 33.5 | 88.9 | 108 | 25.4 | 4 | 7/8″ | 5.4 | 12 |

| 1-1/4″ | 32 | 184.2 | 38.1 | 73.2 | 42.2 | 95.3 | 130 | 28.4 | 4 | 1″ | 7.8 | 17.2 |

| 1-1/2″ | 40 | 203.2 | 44.5 | 79.2 | 48.3 | 111.3 | 146.1 | 31.8 | 4 | 1 1/8″ | 11.5 | 25.4 |

| 2″ | 50 | 235 | 50.8 | 95.3 | 60.5 | 127 | 171.5 | 28.4 | 8 | 1″ | 19 | 42 |

| 2-1/2″ | 65 | 266.7 | 57.2 | 114.3 | 73.2 | 142.7 | 196.9 | 31.8 | 8 | 1 1/8″ | 24 | 52 |

| 3″ | 80 | 304.8 | 66.5 | 133.4 | 88.9 | 168.1 | 228.6 | 35.1 | 8 | 1 1/4″ | 42.6 | 94 |

| 4″ | 100 | 355.6 | 76.2 | 165.1 | 114.3 | 190.5 | 273.1 | 41.1 | 8 | 1 1/2″ | 64 | 141 |

| 5″ | 125 | 419.1 | 91.9 | 203.2 | 141.2 | 228.6 | 323.9 | 47.8 | 8 | 1 3/4″ | 111 | 244 |

| 6″ | 150 | 482.6 | 108 | 235 | 168.4 | 273.1 | 368.3 | 53.8 | 8 | 2″ | 171 | 378 |

| 8″ | 200 | 552.5 | 127 | 304.8 | 219.2 | 317.5 | 438.2 | 53.8 | 12 | 2″ | 261 | 576 |

| 10″ | 250 | 673.1 | 165.1 | 374.7 | 273.1 | 419.1 | 539.8 | 66.5 | 12 | 2 1/2″ | 485 | 1068 |

| 12″ | 300 | 762 | 184.2 | 441.5 | 323.9 | 463.6 | 619.3 | 73.2 | 12 | 2 3/4″ | 698 | 1539 |

Note:

1) 7 mm raised face regularly furnished above Class 400 unless otherwise ordered.

Weld Neck Flanges Application

|

|

PRODUCTS WE MANUFACTURE

- FORGED FLANGES

- BLIND FLANGES

- SLIP ON FLANGES

- WELD NECK FLANGES

- LAPPED JOINT FLANGES

- THREADED FLANGES

- SOCKET WELD FLANGES

- LONG WELD NECK FLANGES

- WELDO / NIPO FLANGES

- ORIFICE FLANGES

- REDUCING FLANGES

- FLAT FLANGES

- LOOSE FLANGES

- RTJ FLANGES

- SORF FLANGES

- SQUARE FLANGES

- EXPANDER FLANGES

- WNRF FLANGES

- GROOVE & TONGUE FLANGES

- HIGH HUB BLINDS FLANGES

- SPECTACLE BLIND FLANGES

- WELD NECK FLANGES A / B

- SPADES RING SPACERS FLANGES

- SCREWED FLANGES

- FORGING FACING FLANGES