Highly acclaimed Manufacturer & Supplier of Blind Flanges, BLRF Flanges, Carbon Steel Blind Flanges, Stainless Steel Blind Flanges, Alloy Steel Blind Flanges, Nickel Blind Flanges, Inconel Blind Flanges, Hastelloy Blind Flanges in India & Asia

We are largest manufacturers of Blind Flanges & have huge stock of 304 Blind Flanges, 316 Blind Flanges, astm a105 Blind Flanges, astm a182 Blind Flanges as per asme / ansi B16.5 blind flanges, ansi B16.47 blind flanges, Din blind flanges, jis blind flanges & uni blind flanges Standards.

we offer high quality Blind Flanges in all size, classes & dimensions like Class 150 Blind Flanges, Class 300 Blind Flanges, Class 900 Blind Flanges, Class 1500 Blind Flanges, Class 2500 Blind Flanges, pn16 blind flange dimensions & pn40 blind flange dimensions

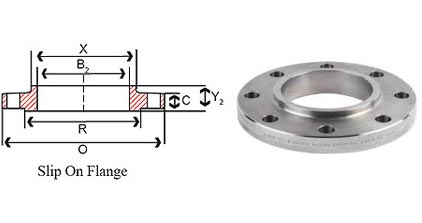

Slip On Flanges / SORF Flanges

- Slip On Flanges Flanges Price

- Leading manufacturer of Slip On Flanges

- Our Live Stock of Slip On Flanges

- Slip On Flanges Application

We are Manufacturer, Supplier and Exporter of Slip-on pipe flange, ASME 16.5 Slip On Flanges / SORF Flanges. Slip-on pipe flange usually slips over the pipe. Slip-on pipe flanges are typically made with an inside diameter of the pipe flange slightly larger than the outside diameter of the pipe. This allows the slip-on flange to slip over the pipe. Slip-on pipe flanges are welded (usually both inside and outside) to provide strength and prevent leakage. Slip-on pipe flanges can sometimes also have a boss/ring or hub, and can be made with a bore to suit either pipe or tube. Ring pipe flanges and hub pipe flanges are both considered slip-on pipe flanges because they both slip over the pipe. Slip-on flanges are easy to use in fabricated applications. These flanges are attached to the pipe by fillet welding at the hub and at the end of the pipe inside the flange. These are available in wide variety of sizes and applications.

Slip-on flanges are generally preferred by users over weld neck flanges, as they are a cheaper option than weld neck flange and the fact that less accuracy is required when cutting pipe to length.

Slip-on flanges are available with raised, flat or RTJ faces, and are also available in orifice configurations.

| Product Type | Slip-on pipe flange, ASME 16.5 Slip On Flanges / SORF Flanges |

|---|---|

| Size | ½” (15 NB) to 48″ (1200NB) |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Stainless Steel Slip on Flanges | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Carbon Steel Slip on Flanges | ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70 |

| Alloy Steel Slip on Flanges | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel Slip on Flanges | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Specialize | As per drawing |

| Standard | ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 ,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820 DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S : BS4504 , BS4504, BS1560, BS10 |

| Connection Type / Flange Face Type | Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large Tongue & Groove, Small Tongue & Groove |

Dimensions of Slip On ASME B16.5

Dimensions of Slip On ASME B16.5 – class 150 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Slip On | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 9.6 | 35.05 | 30 | 22.2 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 11.2 | 42.93 | 38 | 27.7 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 12.7 | 50.80 | 49 | 34.5 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 14.3 | 63.50 | 59 | 43.2 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 15.9 | 73.15 | 65 | 49.5 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 17.5 | 91.95 | 78 | 61.9 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 20.7 | 104.65 | 90 | 74.6 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 22.3 | 127.00 | 108 | 90.7 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 22.3 | 139.70 | 122 | 103.4 | 30 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 22.3 | 157.22 | 135 | 116.1 | 32 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 22.3 | 185.67 | 164 | 143.8 | 35 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 23.9 | 215.90 | 192 | 170.7 | 38 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 27.0 | 269.75 | 246 | 221.5 | 43 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 28.6 | 323.85 | 305 | 276.2 | 48 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 30.2 | 381.00 | 365 | 327.0 | 54 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 33.4 | 412.75 | 400 | 359.2 | 56 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 35.0 | 469.90 | 457 | 410.5 | 62 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 38.1 | 533.40 | 505 | 461.8 | 67 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 41.3 | 584.20 | 559 | 513.1 | 71 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 46.1 | 692.15 | 663 | 616.0 | 81 | 20 | 34.92 | 74 |

Dimensions of Slip On ASME B16.5 – class 300 Lbs

| minal Bore Slip On | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 21.3 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 14.3 | 42.93 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 20.7 | 91.95 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 28.6 | 139.70 | 133 | 103.4 | 43 | 8 | 22.22 | 184.2 |

| 4″ | 114.3 | 30.2 | 157.22 | 146 | 116.1 | 46 | 8 | 22.22 | 200.0 |

| 5″ | 141.3 | 33.4 | 185.67 | 178 | 143.8 | 49 | 8 | 22.22 | 235.0 |

| 6″ | 168.3 | 35.0 | 215.90 | 206 | 170.7 | 51 | 12 | 22.22 | 269.9 |

| 8″ | 219.1 | 39.7 | 269.75 | 260 | 221.5 | 60 | 12 | 25.40 | 330.2 |

| 10″ | 273.0 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12″ | 323.8 | 49.3 | 381.00 | 375 | 327.0 | 71 | 16 | 31.75 | 450.8 |

| 14″ | 355.6 | 52.4 | 412.75 | 425 | 359.2 | 75 | 20 | 31.75 | 514.4 |

| 16″ | 406.4 | 55.6 | 469.90 | 483 | 410.5 | 81 | 20 | 34.92 | 571.5 |

| 18″ | 457.0 | 58.8 | 533.40 | 533 | 461.8 | 87 | 24 | 34.92 | 628.6 |

| 20″ | 508.0 | 62.0 | 584.2td> | 587 | 513.1 | 94 | 24 | 34.92 | 685.8 |

| 24″ | 610.0 | 68.3 | 692.15 | 702 | 616.0 | 105 | 24 | 41.27 | 812.8 |

Dimensions of Slip On ASME B16.5 – class 600 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Slip On | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 21.3 | 14.3 | 35.05 | 38 | 22.2 | 22 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 15.9 | 42.93 | 48 | 27.7 | 25 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 17.5 | 50.80 | 54 | 34.5 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 20.7 | 63.50 | 64 | 43.2 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 22.3 | 73.15 | 70 | 49.5 | 32 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 25.4 | 91.95 | 84 | 61.9 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 28.6 | 104.65 | 100 | 74.6 | 41 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 31.8 | 127.00 | 117 | 90.7 | 46 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 35.0 | 139.70 | 133 | 103.4 | 49 | 8 | 25.40 | 184.2 |

| 4″ | 114.3 | 38.1 | 157.22 | 152 | 116.1 | 54 | 8 | 25.40 | 215.9 |

| 5″ | 141.3 | 44.5 | 185.67 | 189 | 143.8 | 60 | 8 | 28.57 | 266.7 |

| 6″ | 168.3 | 47.7 | 215.90 | 222 | 170.7 | 67 | 12 | 28.57 | 292.1 |

| 8″ | 219.1 | 55.6 | 269.75 | 273 | 221.5 | 76 | 12 | 31.75 | 349.2 |

| 10″ | 273.0 | 63.5 | 325.85 | 343 | 276.2 | 86 | 16 | 34.92 | 431.8 |

| 12″ | 323.8 | 66.7 | 381.00 | 400 | 327.0 | 92 | 20 | 34.92 | 489.0 |

| 14″ | 355.6 | 69.9 | 412.75 | 432 | 359.2 | 94 | 20 | 38.10 | 527.0 |

| 16″ | 406.4 | 76.2 | 469.90 | 495 | 410.5 | 106 | 20 | 41.27 | 603.2 |

| 18″ | 457.0 | 82.6 | 533.40 | 546 | 461.8 | 117 | 20 | 44.45 | 654.0 |

| 20″ | 508.0 | 88.9 | 584.20 | 610 | 513.1 | 127 | 24 | 44.45 | 723.9 |

| 24″ | 610.0 | 101.6 | 692.15 | 718 | 616.0 | 140 | 24 | 50.80 | 838.2 |

Slip On Flanges Application

|

|

What & Where we Supply

Slip On Flanges in India | Slip On Flanges Prices in India | Stainless Steel Pipe Fittings Stockist in India | Slip On Flanges Supplier in India | Slip On Flanges Exporter in India | Slip On Flanges Manufacturer in India | Slip On Flanges Distributor in India | Slip On Flanges Trader in India | Slip On Flanges Dealer in India | Slip On Flanges Stockholder in India | Slip On Flanges Importer in India. | Slip On Flanges distributor in Mumbai | Slip On Flanges with Test Certificate | Slip On Flanges Manufacturer in Mumbai | Slip On Flanges in United States | Slip On Flanges in United Arab Emirates | Slip On Flanges in Canada | Slip On Flanges in Pakistan | Slip On Flanges in Spain | Slip On Flanges in France | Slip On Flanges in United Kingdom | Slip On Flanges in Indonesia | Slip On Flanges in Iran | Slip On Flanges in Kuwait | Slip On Flanges in Mexico | Slip On Flanges in Malaysia | Slip On Flanges in Nigeria | Slip On Flanges in Singapore | Slip On Flanges in Saudi Arabia | Slip On Flanges in Netherlands | Slip On Flanges in Brazil | Slip On Flanges in Colombia | Slip On Flanges in Egypt | Slip On Flanges in Iraq | Slip On Flanges in Sri Lanka | Slip On Flanges in Russia | Slip On Flanges in Vietnam | Slip On Flanges in South Africa | Slip On Flanges in Nigeria | Slip On Flanges in Turkey | Slip On Flanges in Bangladesh | Slip On Flanges in Italy | Slip On Flanges in Japan | Slip On Flanges in Thailand | Slip On Flanges in Hong Kong | Slip On Flanges in Switzerland | Slip On Flanges in New Zealand | Slip On Flanges in Mozambique | Slip On Flanges Dubai | Slip On Flanges Taiwan | Slip On Flanges Chile | Slip On Flanges Venezuela | Slip On Flanges Denmark

PRODUCTS WE MANUFACTURE

- FORGED FLANGES

- BLIND FLANGES

- SLIP ON FLANGES

- WELD NECK FLANGES

- LAPPED JOINT FLANGES

- THREADED FLANGES

- SOCKET WELD FLANGES

- LONG WELD NECK FLANGES

- WELDO / NIPO FLANGES

- ORIFICE FLANGES

- REDUCING FLANGES

- FLAT FLANGES

- LOOSE FLANGES

- RTJ FLANGES

- SORF FLANGES

- SQUARE FLANGES

- EXPANDER FLANGES

- WNRF FLANGES

- GROOVE & TONGUE FLANGES

- HIGH HUB BLINDS FLANGES

- SPECTACLE BLIND FLANGES

- WELD NECK FLANGES A / B

- SPADES RING SPACERS FLANGES

- SCREWED FLANGES

- FORGING FACING FLANGES

STAINLESS STEEL FLANGES

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 317 Flanges

- Stainless Steel 317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 347H Flanges

- Stainless Steel 446 Flanges

- Duplex Steel UNS S32205 Flanges

CARBON STEEL & ALLOY STEEL FLANGES

- Carbon Steel Forged Flanges

- 105 Carbon Steel Blind Flanges

- A694 F42 Carbon Steel Slip On Flanges

- A694 F46 Carbon Steel Weld Neck Flanges

- A694 F52 Carbon Steel Lap-Joint Flanges

- A694 F60 Carbon Steel Threaded Flanges

- A694 F65 Carbon Steel Socket Weld Flanges

- A694 F70 Carbon Steel Rtj Flanges

Alloy Steel Long Weld Neck Flanges - A182 F1 Weldo / Nipo Flanges

- A182 F5 Orifice Flanges

- A182 F9 Reducing Flanges

- A182 F11 Ring Type Joint Flanges

- A182 F22 WNRF Flanges

- A182 F91 Lapped Joint Flanges

HIGH NICKEL FLANGES

- Nickel Alloy 200 Forged Flanges

- Nickel Alloy 201 Blind Flanges

- Copper Nickel Slip On Flanges

- Copper Nickel 90/10 Weld Neck Flanges

- Inconel 600 Lap-Joint Flanges

- Inconel 601 Threaded Flanges

- Inconel 625 Socket Weld Flanges

- Incoloy 800 Rtj Flanges

- Incoloy 800h Long Weld Neck Flanges

- Incoloy 800ht Nipo Flanges

- Incoloy 825 Orifice Flanges

- Hastelloy C276 Reducing Flanges

- Hastelloy C22 Ring Type Joint Flanges

- Hastelloy B2 WNRF Flanges

- Monel 400 Lapped Joint Flanges